New floor heating panels from NORDIC FOS

– quick response time, quick installation, big energy savings

In recent years, development in floor heating has seen a shift from heating coils cast into concrete to light floor heating panels that distribute heat quickly. This helps to reduce energy consumption and results in lower heating costs for the consumer.

The new floor heating panels from NORDIC FOS can regulate floor heating temperatures in just 30 minutes. This saves energy, while the panels can easily and quickly be installed at a lower cost.

Developed by Scandinavian universities

NORDIC FOS new floor heating panels have been developed in close collaboration with the technical universities. A team of experts was tasked with developing the perfect floor heating system, both in terms of energy consumption and installation. Therefore, the new range of floor heating panels has been designed to regulate temperature quickly – allowing night setback and continuous adjustment, resulting in much lower heating costs. The principle behind the development work is that the heating coils are placed close to the new floor, with a smaller distance between the heating coils and a smaller coil dimension than before.

Response time of just 30 minutes

Older floor heating systems based on heating coils cast in concrete often have a response time of 24 hours. NORDIC FOS new systems cut that response time to just 30 minutes. Therefore, a room thermostat can easily regulate heat consumption on a continuous basis – e.g. when, during the day, the sun offers natural heating. Or when there are a lot of people in the room. A thermostat can regulate heat consumption continuously, thus saving consumers on heating bills and allowing them to enjoy a much better indoor climate.

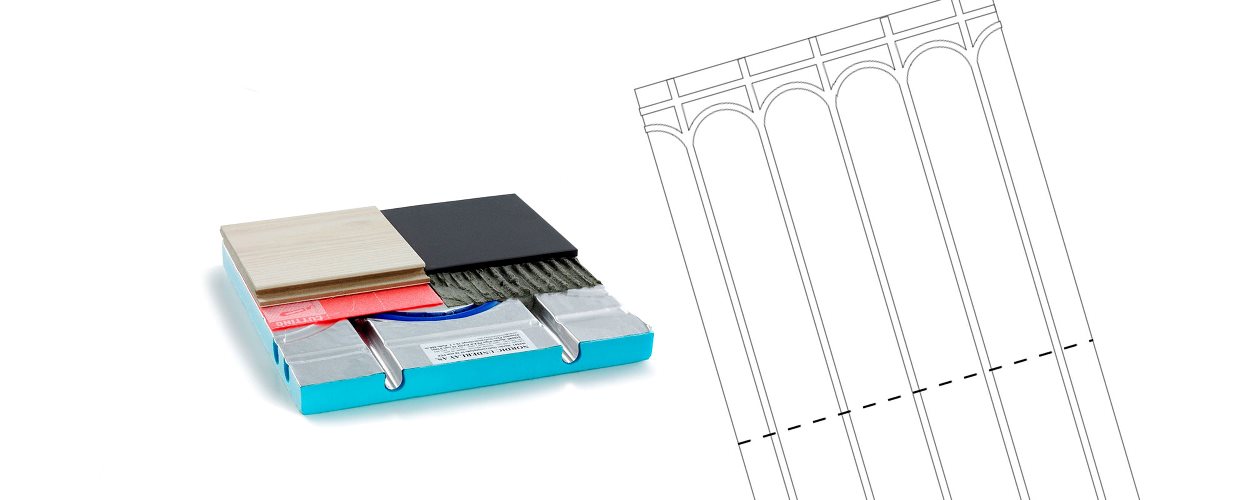

One panel does it all

NORDIC FOS new floor heating panel features aluminium heat distribution across the entire panel, as well as a u-shaped turning track integrated in all panels. This means you now only need one type of panel for the work. The panels are suitable for heating coils with diameters of 12, 16 and 20 mm. They measure 120x60 cm (0.72 m²) and are delivered folded in an easy-to-handle dimension of 60x60 cm and weigh less than 1 kg. All this helps to make installation easier and faster than before.

Suitable for all floor types

NORDIC FOS floor heating panels are made from XPS 500, which has a high compressive strength of 50 t/m2. Unlike other solutions in EPS, XPS has significantly better long-term compressive strength. This is important for floors which are subjected to loads. Compared to EPS, XPS has minimal moisture absorption, and is therefore suitable for solutions with both cooling and heating. As a result, you can install all kinds of floors immediately on top of the heating panels: tiles, natural stone, parquet and laminate flooring. Herringbone parquet glued to a floor panel; even a thin layer of concrete can be cast to create an industrial, fashionable, New York-style floor.

Extra thin version for renovations

For renovations in older homes, installation height is often a significant challenge. For these tasks, NORDIC FOS floor heating panels come in a special type which is just a few mm thicker than the heating coil itself – i.e. 16 mm in height for 12 mm heating coils and just 19 mm in height for 16 mm heating coils. The standard thickness is 25 mm.

Suitable for all forms of energy, including low energy

What is unique to NORDIC FOS floor heating panels is their ability to utilise heat from low energy systems, geothermal, solar and heat pump systems, where flow temperature can be kept as low as 30–35 degrees compared to 50–60 degrees for traditional radiator systems.

NORDIC FOS underfloor heating coils – always five layers

For floor heating installations without casting, it is always important to use five-layer underfloor heating coils. This way you avoid creaking sounds when the thermostat turns on and off. Compared to three-layer coils, the additional cost of five-layer coils is small, and you get a much better result.